|

General Disclaimer: (HV) (DC) injury or death hazard, use at your own risk, may void warranty. |

Difference between revisions of "Escape PHEV TechInfo"

DavideAndrea (talk | contribs) (Moved CAN Network Module Communication Message Chart within the CAN messages section, before the Battery messages section) |

DavideAndrea (talk | contribs) (→418-00-48: Inst was written "Ints" once) |

||

| Line 735: | Line 735: | ||

| A/C clutch status || PCM || HS-CAN || TBCM || || || || | | A/C clutch status || PCM || HS-CAN || TBCM || || || || | ||

|- | |- | ||

| − | | ABS/trac event in progress || BSCM|| HS-CAN || | + | | ABS/trac event in progress || BSCM|| HS-CAN || Inst, PCM || || || || |

|- | |- | ||

| ABS/trac indicator on request || BSCM|| HS-CAN || Inst || || || || | | ABS/trac indicator on request || BSCM|| HS-CAN || Inst || || || || | ||

Revision as of 13:07, 6 February 2007

Contents

- 1 Traction battery

- 1.1 Specs

- 1.2 Removal

- 1.3 Component locations

- 1.4 Block diagram

- 1.5 Wiring diagram

- 1.6 Connectors

- 1.7 Electronic Components

- 1.8 Battery HVAC system

- 1.9 CAN bus messages

Technical information on the Ford Escape useful when designing a Escape PHEV conversion.

Unless otherwise noted, everything refers to a 2007 year model, belonging to Hybrids Plus.

Traction battery

Specs

- Cells:

- 250 Sanyo NiMH 'D' cells

- 300 V nominal @ 1.2V/cell (Ford says 330V)

- 5.5 Ah

- Electronics:

- controller

- DC-DC converter to charge traction battery from 12 V battery ("Jump Start")

- Contactors and pre-charge relay / resistor

- Current sensor

- Blowers

- Connectors:

- 12 V power and control (40 circuits)

- HV (4 circuits)

- AC/DC (2 circuits, unused)

- Mechanical

- 87 kg (192 lb)

- 102 x 80 x 15 cm (40 x 31-1/2 x 6")

Removal

From the hatch opening:

- Remove the carpet in the hatch compartment floor, to reveal the battery

- Turn the orange safety plug from LOCK to UNLOCK and pull it out

- Remove the black plastic air coupling on the rear-left

- Remove the bolts on either side of the battery (3 bolts on each side)

- Lift the bottom of the rear-right passenger seat and move it forward

- List the strip of carpet to reveal the metal cover over the high voltage cables

- Remove the 2 (not 3) nuts holding the black metal cover

- Flip the seat forward to see the other end of the black metal cover

- Remove the 2 bolts holding the other end of the black metal cover to the battery

- Disconnect the battery:

- From the rear right seat, remove the orange HV connector on the right (flip the lever)

- From the rear left seat, remove the big black signal connector on the left (unbolts with a 10 mm socket wrench)

- From the rear left seat, remove the small connector next to the signal connector (snaps)

- Remove the battery

- Remove the 6 bolts, 3 on each side of the battery, bolting it to the floor (1/2" socket)

- Hook an engine hoist to the two round holes in the black metal on either side of the battery

- Hoist the battery out of the car

To open the battery:

- You need a #35 security Torx driver, and a #35 Torx driver

- Remove all the screws in the 2 top covers:

- Cover over the fans

- Cover over the batteries and electronics

Component locations

The battery includes (as seen when in the vehicle):

- Air blowers in the rear compartment

- NiMH cells in the center

- 2 layers of cells

- each layer in a left and right group

- the groups in the top layer have 13 columns of 5 cells in series

- the groups in the bottom layer have 12 columns of 5 cells in series

- total: 2 * 13 * 5 + 2 * 12 * 5 = 250 cells

- nominal pack voltage: 1.2 V * 250 = 300 V

- controller on the right side

- contactors and HV connector on the right-front corner

- HV safety plug on the right-rear corner. The current sensor is inside it

- the Converter on the left side

Block diagram

This block diagram shows the main components of the battery pack, and how they interface to the vehicle

- The NiMH cells store energy

- The battery controller controls the battery pack

- It communicates with the vehicle through the CAN bus

- It monitors the air intake temperature, it controls the intake air flow and source, and it drives to DC blowers to blow air into the cells

- It monitors the cells' voltage, including in intermediate points of the pack ("taps")

- ...

- The DC-DC converter receives power from the 12 V battery and boosts it up to 300 V, to charge the traction battery when it's dead and the user presses the Jump Start button (by the driver's left foot)

- The Safety Disconnects opens the pack mid-voltage

- The HV Output section

- It has a connector with 2 high-current contacts to connect the battery voltage to the vehicle

- It has a pair of wires to determine if that connector is connected or not

- It has contactors (high power relays) to connect or isolate the pack voltage

- The blower compartment has 2 DC blowers to blow air into the cells

Wiring diagram

This wiring diagram shows how the components of the battery pack are wired together.

- High voltage wires are red.

- Connectors are marked with their color and the number of positions

- Sets of wires are shown together. The slash at one end indicates the number of wires

- The function of sets of wires is shown above the wire

- The wire colors are shown below the set of wires

- Shaded squares indicate that wires are bundled together

- The orientation of the components is shown as seen when looking from the hatch

This reverse engineering drawing is not guaranteed to be accurate and is offered as-is. Please direct corrections to DavideAndrea.

Connectors

The battery has 3 connectors, with a total of 34 wires:

- C4227A - 28 wires - control

- C4227B - 2 wires - low power HV to the AC/DC converter

- C4227C - 4 wires - traction HV, interlock signals

AC/DC converter connector: C4227B

Pin-out. Looking into cable (left) and looking into battery (right)

The AC/DC converter connector has 2 circuits, with the following names and functions.

| Group | Ckt | Pin(s) | Ext. color | Int. color | Name | Function | Notes | |

| AC/DC converter in | 3000 | 1 | Vio | Red | AC/DC in+ | To connect a 115 Vac charger for the traction battery? | Ends in hood, by coolant tanks, unconnected and capped | ?? |

| 3001 | 1 | VioOrg | Blk | AC/DC in- | ?? |

This connector is on one end of a cable. The other end of the cable (C1468) is capped, under the hood, on the right, in front of the 2 coolant tanks, fastened to its own harness.

I don't know what is supposed to go in it: some option? I don't know if this is an input or an output. The name (A/C converter), the fact that inside the traction battery the wires are black and red, and the relatively small size of the wires in the cable outside the battery, suggest that it's for a high-voltage, low current, traction battery charger. Maybe Ford provides a box, with just a bridge rectifier, 115 Vac in and 180 Vdc out, to charge the traction battery from the wall. D'de

Control connector: C4227A

Pin-out. Looking into cable (left) and looking into battery (right)

The big control connector has 24 circuits, with the following names and functions.

| Group | Ckt | Pin(s) | Ext. color | Int. color | Name | Function | Notes | |

| 12V pwr | 57 | 35,36,37 | LtgrnBlk | Blk | Ground | Power ground | OK | |

| 570 | 30,31 | BlkWht | BlkWht | Ground | Signal ground | OK | ||

| 3800 | 4,5,6 | LtgrnBlk | Red | +12 V | Power +12V | Always on | OK | |

| 16 | 10,11 | +12 V | RedLtgrn | RedBlu | Low power +12V | Always on | OK | |

| 3206 | 19 | LtgrnYel | TanRed | Voltage supplied in Start and Run | Receives 12 V when the ignition switch is in either the On or Start positions (even if engine is not running) | From the ignition switch. Overload protected | OK | |

| 3997 | 14 | Dkgrn | Tan | Power sustain relay out | Receives 12 V when the ignition switch is in either the On or Start positions (even if engine is not running) and for 2 seconds after the ignition is turned off | Fed by the Powertrain Control Module's Power Relay, located in the Battery Junction Box. The Powertrain Control Module is located under the hood, in the rear-center | OK | |

| Air intake | 3703 | 21 | BrnWht | BlkBrn | Battery compartment thermistor signal | Senses air intake temperature | All are located inside the column at the rear-left corner of car, inside air intake ducts | n.a. |

| 3704 | 25 | DkgrnWht | WhtBlk | Battery compartment thermistor return | n.a. | |||

| 698 | 34 | Red | RedBlu | Mode door actuator motor + | Moves a flap controlling air flow | n.a. | ||

| 699 | 26 | Org | BlkYel | Mode door actuator motor - | n.a. | |||

| 1129 | 17 | BrnWht | RedGRn | Mode door actuator potentiometer + | Senses position of flap | n.a. | ||

| 1130 | 20 | PnkLtgrn | BluBlk | Mode door actuator potentiometer wiper | n.a. | |||

| 1128 | 24 | GryLtBlu | BlkWht | Mode door actuator potentiometer - | n.a. | |||

| 698 | 34 | Red | RedBlu | Zone Valve | Solenoid selecting air source | n.a. | ||

| CAN BUS | 1908 | 29 | Wht | YelRed | High speed CAN bus + | Communicates with vehicle | See CAN section below for messages | OK |

| 1909 | 28 | Blk | YelWht | High speed CAN bus - | OK | |||

| Jump start switch | 176 | 16 | PnkLtgrn | BrnWht | Jump start switch feed | When grounded, lets 12 V battery jump charge-up the traction battery a bit, through DC-DC converter in battery pack, enough to start the car | The switch is located to the left of the driver's left ankle, behind a black plastic panel | OK |

| 179 | 12 | OrgRed | GrnBlk | Jump start switch illumination + | When at 12 V, it lights-up the switch | OK | ||

| Emergency control | 3003 | 8 | VioWht | Tan | Battery power off signal | 0-12 V square wave, 50% duty cycle, generated by battery. If all OK, 2 Hz. If problem, 5 Hz? | The Power Train Control Module is located under the hood, in the rear-center | OK |

| 877 | 7,23 | Wht | RedBlk | Fuel pump feed / Inertia Sw input | Normally receives 12 V when the ignition switch is in either the On or Start positions (even if engine is not running) and for 2 seconds after the ignition is turned off; no voltage when the ignition is off, or in case a crash opens an inertia switch | The High Voltage Cutoff switch is located in the right-rear column of the car | OK | |

| 212 | 27 | Dkblu | BlkBlu | Immediate shutdown 1 | The Transaxle Control Module tells the battery to remove power to the vehicle? | The Transaxle Control Module is under the hood, in the center, to the left of the box labeled "HYBRID" | OK | |

| 213 | 13 | DkbluYel | BlkRed | Immediate shutdown 2 | OK | |||

| Unused | n.a. | 18 | n.a. | TanRed | ??? | ??? | Connected to controller, not used in vehicle | ?? |

| 32 | YelBlk | ?? |

Notes

- Green OK: function is understood and confirmed

- Red ??: function is not understood, or not yet confirmed

- Gray n.a.: PHEV conversion can work without this function

HV connector: C4227C

Pin-out. Looking into cable (left) and looking into battery (right)

The HV connector has 4 circuits, with the following names and functions.

| Group | Ckt | Pin(s) | Ext. color | Int. color | Name | Function | Notes | |

| HV | 3180 | + | Org | n.a. | HV+ | Battery power | To Transaxle Control Module | OK |

| 3181 | - | Org | HV- | OK | ||||

| Interlock | 3130 | 1 | Gry | Blu | Traction Battery Control Module Interlock + | Detects if HV connector is mated. The battery and the Transaxle Control Module both look at the voltage at these pins. | To Transaxle Control Module | OK |

| 3181 | 2 | Red | Wht | Traction Battery Control Module Interlock - | OK |

The electrical circuit for the HV Interlock. The circuit goes from the battery, through the Transaxle Control Module, and back to the battery. If either wire is opened, shorted to +12 V or grounded, both the Battery and the Transaxle Control Module detect a fault.

Electronic Components

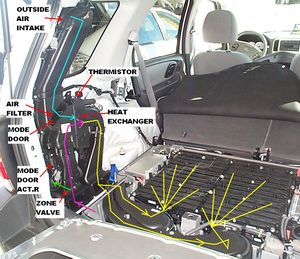

Battery HVAC system

The HVAC system controls the temperature of the NiMH cells in the traction battery.

Its components are located:

- in the rear-left column

- in the traction battery itself

When used in a closed loop, air flows:

- from the empty spaces in the battery pack

- out of the rear-most grille in the rear-right corner of the battery pack

- into a duct in the rear-right column of the vehicle

- up the rear duct in that colums

- through the Mode Door that controls the air flow (unconfirmed)

- through the Zone Valve that selects the air source (unconfirmed)

- forward through a heat exchanger

- down the front duct

- out of the rear-right column

- into the front-most grille in the rear-right corner of the battery pack

- into the battery pack

- into 2 ducts, one for each blower

- into 2 blowers, one for each duct

- into each set of cells (left set for left blower, right for right)

- through the cells and into the empty spaces in the battery pack

- completing the cycle

The heat exchanger is either chilled by the vehicle's air conditioning system, or heated by the vehicle's engine coolant

(GPSMAN): Are you 100% sure that engine heat is used to heat the HV battery? I have official workshop manuals and have never seen anything that refers to artificial heating... just cooling. There are refridgerant lines from the A/C compressor under the hood to provide cooling only as far as I know. I live in a sub-zero climate, and the battery does not perform well in cold.

When using outside air:

- air is taken from a vent in the rear-right window

- down a duct

- flows through an air filter

- through the Mode Door

- into the heat exchanger

- then following the same path as above

Now that extra air has been taken into the system, air has to be let out of it

- air from the pack flows into the rear duct

- the Zone Valve opens, letting out air from the rear duct into the open space in rear-right column

- from there, air flows into the rear storage area

To monitor the temperature, thermistors are placed:

- 1 in the rear-right ducts

- 2 by the blowers, one for each blower

- 2 in the left block of cells, 2 in the right block (unconfirmed)

To control the air flow and temperature:

- the blower's speed is variable

- the Mode Door's position is continuously variable from closed to fully open

- the Zone Valve selects the air source

CAN bus messages

The battery communicates to the rest of the vehicle through the CAN bus. The

- Kvaser has a simple explanation of the CAN bus.

- wikipedia article on the CAN bus

CAN Tools

- A generic adapter between the CAN-bus and a PC. It is convenient to use a USB port, though the serial or parallel or Ethernet port may be used as well. Examples of USB adapters:

- Peak's PCAN-USB also sold as the GridConnect's GC-CAN-USB

- Note: disconnecting this product's USB cable seems to create significant problems for Windows XP (immediate shut-down, or even the "blue screen of death"). You must use the system tray's "Remove hardware" icon first.

- Grifo's CANUSB

- Systec's USB-CANmodul

- CAN232 is a CAN to RS232 device used by Attila Vass with his early My CAN Project.

- The CAN-View should not be confused with this CANview product (notice no dash in the name), which is a CAN to RS232 device.

- Peak's PCAN-USB also sold as the GridConnect's GC-CAN-USB

- These adapters have a DE-9 DSUB connector, so you'll also need an adapter to the Prius' OBD connector. For example:

- The Prius' OBD (On Board Diagnostics) connector is located under the dashboard, below and to the right of the steering wheel, facing down. A.k.a.: Data Link Connector 3 (DLC3)

- Alternatively, tap into the CAN bus directly. Use a short cable to the CAN adapter.

- CAN -: black wire

- CAN +: white wire

- GND - chassis

CAN bus protocol

- The CAN bus is active only when the vehicle is in on (Start or Run position of the ignition key), and for a few seconds after the vehicle is turned off.

- baud rate: 500 kbits/s (if you use the wrong rate, the vehicle will complain and store a DTC fault until the DTC codes are cleared)

- Standard: CAN 2.0A ("standard CAN", 11-bit identifier)

- Remote frames: not used

- this means all the data are volunteered and none are requested; that is, that every component on the vehicle broadcasts its data periodically; no component puts out requests for data

CAN bus messages

The CAN bus has only 24 messages.

This screen capture was taken with the ignition on On, engine off, on Hybrids Plus' Escape.

CAN Network Module Communication Message Chart

From 2007 Escale, Mariner, Escape Hybrid, Mariner Hybrid Workshop Manual, Volume 1

Key:

| |||||||

| Broadcast Message | Orienting module |

Network Type |

Receiving Module(s) |

ID | Length | Period | Data |

418-00-7 | |||||||

| ABS/trac event in progress | ABS | HS-CAN | Inst, PCM | ||||

| ABS/trac indicator on request | ABS | HS-CAN | Inst | ||||

| ABS/trac system configuration | ABS | HS-CAN | Inst | ||||

| ABS/trac system status | ABS | HS-CAN | Inst, PCM | ||||

418-00-8 | |||||||

| Actual torque | PCM | HS-CAN | ABS | ||||

| Anti-stall active | PCM | HS-CAN | ABS | ||||

| Axel ratio | PCM | HS-CAN | ABS | ||||

| Barometric pressure | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Barometric pressure (gateway) | Inst | MS-CAN | SJB | ||||

| Brake deactivator switch status | ABS | HS-CAN | Inst, PCM | ||||

| Brake fluid level status | ABS | HS-CAN | Inst | ||||

| Brake indicator on request | ABS | HS-CAN | Inst | ||||

| Brake switch status | ABS | HS-CAN | PCM, Inst, 4wd | ||||

| Brake thermal intervention active y/n | ABS | HS-CAN | Inst, PCM | ||||

| Catalyst protection active y/n | PCM | HS-CAN | ABS | ||||

| Charging system status | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Clutch pedal position | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Door ajar status | SJB | MS-CAN | Inst | ||||

| Drivetrain type | PCM | HS-CAN | ABS | ||||

| Electronic brake distribution status | ABS | HS-CAN | Inst, PCM | ||||

| Engine coolant temp | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Engine off timer | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Engine RPM | PCM | HS-CAN | ABS, Inst, 4wd | ||||

418-00-9 | |||||||

| Failsafe cooling mode | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Fuel cap off indicator request | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Fuel flow data | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Fuel level input status (filtered) | Inst | HS-CAN | PCM | ||||

| Fuel level input status (instant) | Inst | HS-CAN | PCM | ||||

| Headlamp status | SJB | MS-CAN | Inst | ||||

| Key-in-ignition status | SJB | MS-CAN | Inst | ||||

| Maximum available torque | PCM | HS-CAN | ABS | ||||

| Minimum available torque | PCM | HS-CAN | ABS | ||||

| MIL warning indicator on request | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Odometer count | ABS | HS-CAN | Inst, 4wd cont | ||||

| Overdrive indicator status | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Park lamp status | SJB | MS-CAN | Inst | ||||

| PATS indicator status | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| PATS key status | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| PATS key status (gateway) | SJB | MS-CAN | Inst | ||||

| Perimeter alarm status | SJB | MS-CAN | Inst | ||||

| Shift and converter status | PCM | HS-CAN | ABS | ||||

418-00-10 | |||||||

| Throttle position | PCM | HS-CAN | ABS, Inst, 4wd | ||||

| Torque reduction request | ABS | HS-CAN | PCM, Inst, 4wd | ||||

| Torque transfer actual | 4WD | HS-CAN | ABS, Inst | ||||

| TPMS sensor status(LF,RF,RR,LR) | SJB | MS-CAN | Inst | ||||

| TPMS system status | SJB | MS-CAN | Inst | ||||

| Transmission gear ratio | PCM | HS-CAN | ABS | ||||

| Transmission selector range | PCM | HS-CAN | ABS | ||||

| Transmission selector range (gateway) | Inst | MS-CAN | SJB | ||||

| Turn signal indicator | SJB | MS-CAN | Inst | ||||

| Vehicle speed | ABS | HS-CAN | Inst, 4wd | ||||

| Vehicle speed (gateway) | Inst | MS-CAN | SJB | ||||

| VIN information | PCM | HS-CAN | ABS, 4wd | ||||

| Wheel speed output (RF,LF,RR,LR) | ABS | HS-CAN | 4wd | ||||

| 4WD indicator request | 4WD | HS-CAN | ABS, Inst | ||||

418-00-48 | |||||||

| A/C clutch status | PCM | HS-CAN | TBCM | ||||

| ABS/trac event in progress | BSCM | HS-CAN | Inst, PCM | ||||

| ABS/trac indicator on request | BSCM | HS-CAN | Inst | ||||

| Accelerator pedal mode | PCM | HS-CAN | TBCM | ||||

| Accelerator pedal position | PCM | HS-CAN | TBCM | ||||

| Accelerator torque requested | PCM | HS-CAN | BSCM | ||||

| Barometric pressure | PCM | HS-CAN | Inst | ||||

| Barometric pressure (gateway) | Inst | MS-CAN | SJB | ||||

| Battery % available | PCM | HS-CAN | Inst | ||||

| Battery % available (gateway) | Inst | MS-CAN | CANtoACP gateway module | ||||

| Battery a/c request | TBCM | HS-CAN | PCM | ||||

| Battery caution warning indicator on request | PCM | HS-CAN | Inst | ||||

| Battery caution warning indicator on request | TBCM | HS-CAN | Inst | ||||

| Battery charge power capacity #12 | TBCM | HS-CAN | PCM | 310h | 7 | 100 | 310:00:00:00:00:00:00:00 byte 5 |

| Battery current #2 | TBCM | HS-CAN | Inst, PCM, TCM | 300h | 5 | 10 | 300:00:00:00:00:00 bytes 0-1 |

| Battery discharge power capacity #13 | TBCM | HS-CAN | PCM | 310h | 7 | 100 | 310:00:00:00:00:00:00:00 byte 6 |

| Battery freeze condition yes/no | TBCM | HS-CAN | PCM | ||||

418-00-49 | |||||||

| Battery hazard warning indicator on request | TBCM | HS-CAN | Inst | ||||

| Battery R mode enable | PCM | HS-CAN | TBCM | ||||

| Battery R mode enable | TBCM | HS-CAN | PCM | ||||

| Battery R mode target charge power | TBCM | HS-CAN | PCM | ||||

| Battery refrigerant solenoid state | TBCM | HS-CAN | PCM | ||||

| Battery state of charge % #17 | TBCM | HS-CAN | Inst, PCM | 320h | 5 | 100 | 320:00:00:00:00:00 bytes 3-4 |

| Battery temperature #11 | TBCM | HS-CAN | Unst, PCM | 310h | 7 | 100 | 310:00:00:00:00:00:00:00 byte 4 |

| Battery voltage #3 | TBCM | HS-CAN | Inst, PCM, TCM | 300h | 5 | 10 | 300:00:00:00:00:00 byte 2 |

| Brake fluid level status | BSCM | HS-CAN | Inst | ||||

| Brake indicator on request | BSCM | HS-CAN | Inst | ||||

| Brake switch status | BSCM | HS-CAN | PCM, TCM | ||||

| Brake system status | BSCM | HS-CAN | 4wd | ||||

| Brake travel sensor status | BSCM | HS-CAN | 4wd | ||||

| Charge indicator on request | PCM | HS-CAN | Inst | ||||

| Charging system status | PCM | HS-CAN | Inst | ||||

| Contactor control on/off | PCM | HS-CAN | TBCM, TCM | ||||

| Contactor status on/off | TBCM | HS-CAN | PCM, TCM | ||||

| Door ajar status | SJB | MS-CAN | Inst | ||||

| Engine coolant temp | PCM | HS-CAN | Inst, TCM | ||||

| Engine estimated torque | TCM | HS-CAN | PCM | ||||

| Engine load % | PCM | HS-CAN | TCM | ||||

| Engine on/off status | PCM | HS-CAN | TCM | ||||

418-00-50 | |||||||

| Engine RPM | PCM | HS-CAN | BSCM, Inst, TBCM, TCM | ||||

| Engine RPM desired | PCM | HS-CAN | TCM | ||||

| Engine RPM desired | TCM | HS-CAN | PCM | ||||

| Engine cylinder sync counter | PCM | HS-CAN | TCM | ||||

| Engine torque commanded | PCM | HS-CAN | Inst, TCM | ||||

| Engine torque commanded (gateway) | Inst | MS-CAN | CANtoACP gateway module | ||||

| Engine torque min/max request | TCM | HS-CAN | PCM | ||||

| Engine/Generator mode | PCM | HS-CAN | TBCM, TCM | ||||

| Estimated engine torque | PCM | HS-CAN | TCM | ||||

| Failsafe cooling mode | PCM | HS-CAN | TCM | ||||

| Front a/c on/off status | PCM | HS-CAN | TBCM | ||||

| Fuel cap off indicator on request | PCM | HS-CAN | Inst | ||||

| Fuel cutoff request | TCM | HS-CAN | PCM | ||||

| Fuel flow data | PCM | HS-CAN | Inst | ||||

| Fuel level input status | Inst | HS-CAN | PCM (DTC:Powertrain) | ||||

| Generator brake command | PCM | HS-CAN | TCM | ||||

| Generator coil temperature | TCM | HS-CAN | PCM | ||||

| Generator error status | TCM | HS-CAN | PCM | ||||

| Generator inverter temperature | TCM | HS-CAN | PCM | ||||

| Generator speed | TCM | HS-CAN | PCM | ||||

| Generator torque commanded | TCM | HS-CAN | Inst, PCM | ||||

| Generator torque commanded (gateway) | Inst | MS-CAN | CANtoACP gateway module | ||||

| Generator/engine shutdown status on/off | PCM | HS-CAN | TCM | ||||

418-00-51 | |||||||

| Hazard warning indicator on request | PCM | HS-CAN | Inst | ||||

| Headlamp status | SJB | MS-CAN | Inst | ||||

| Inverter enable request | PCM | HS-CAN | TCM | ||||

| Inverter voltage request | TCM | HS-CAN | PCM, TBCM | ||||

| Jump start status | TBCM | HS-CAN | Inst, PCM | ||||

| Key-in-ignition status | SJB | MS-CAN | Inst | ||||

| MIL warning indicator on request | PCM | HS-CAN | Inst | ||||

| Motor coil temperature | TCM | HS-CAN | PCM | ||||

| Motor coolant temperature | TCM | HS-CAN | Inst, PCM | ||||

| Motor error status | TCM | HS-CAN | PCM | ||||

| Motor inverter temperature | TCM | HS-CAN | PCM | ||||

| Motor speed | TCM | HS-CAN | Inst, PCM | ||||

| Motor torque min/max request | TCM | HS-CAN | PCM | ||||

| Motor torque commanded | TCM | HS-CAN | Inst, PCM | ||||

| Motor torque commanded (gateway) | Inst | MS-CAN | CANtoACP gateway module | ||||

| Odometer count | TCM | HS-CAN | Inst, TBCM | ||||

| Over temp warning request | PCM | HS-CAN | Inst | ||||

| Over voltage protection active | TCM | HS-CAN | PCM | ||||

| Park brake status | Inst | HS-CAN | BSCM, PCM | ||||

| Park lamp status | SJB | MS-CAN | Inst | ||||

| PATS indicator status | PCM | HS-CAN | Inst | ||||

| PATS key status | PCM | HS-CAN | Inst | ||||

| PATS key status (gateway) | Inst | MS-CAN | SJB | ||||

| Perimeter alarm | SJB | MS-CAN | Inst | ||||

| Power steering malfunction | PSC | HS-CAN | Inst | ||||

418-00-52 | |||||||

| PRNDL direction | PCM | HS-CAN | BSCM | ||||

| PRNDL direction confirm | BSCM | HS-CAN | PCM | ||||

| Regenerative brake failure | PCM | HS-CAN | Inst | ||||

| Regenerative fault | BCSM | HS-CAN | PCM | ||||

| Regenerative torque limit | PCM | HS-CAN | BSCM | ||||

| Rolling direction | PCM | HS-CAN | BSCM | ||||

| Rolling direction confirm | BSCM | HS-CAN | PCM | ||||

| Speed control indicator on request | PCM | HS-CAN | Inst | ||||

| TBCM status | TBCM | HS-CAN | PCM | ||||

| TCM caution request | TCM | HS-CAN | PCM | ||||

| TCM hazard request | TCM | HS-CAN | PCM | ||||

| TCM status | TCM | HS-CAN | PCM | ||||

| Throttle position | PCM | HS-CAN | TCM | ||||

| Torque transfer percentage commanded | 4wd | HS-CAN | BSCM | ||||

| Torque transfer percentage request | BSCM | HS-CAN | 4wd | ||||

| TPMS sensor status (LF,RF,RR,LR) | SJB | MS-CAN | Inst | ||||

| TPMS system status | SJB | MS-CAN | Inst | ||||

| Traction battery fault status | TBCM | HS-CAN | PCM | ||||

| Transmission oil temperature | TCM | HS-CAN | PCM | ||||

| Transmission selector range | PCM | HS-CAN | BSCM,Inst,TBCM,TCM,4wd | ||||

| Transmission selector range (gateway) | Inst | MS-CAN | SJB | ||||

| Turn signal indicator request | SJB | MS-CAN | Inst | ||||

| Vehicle speed | TCM | HS-CAN | Inst, PCM, PSC | ||||

| Vehicle speed (gateway) | Inst | MS-CAN | SJB | ||||

418-00-53 | |||||||

| VIN information | PCM | HS-CAN | BSCM, 4wd | ||||

| Wheel speed output (RF,LF,RR,LR) | BCSM | HS-CAN | 4wd | ||||

| 4wd indicator request | 4wd | HS-CAN | Inst | ||||

Battery CAN messages

These are the messages generated by the battery.

The Battery ECU (Electronic Control Unit) broadcasts the following messages. In this table, numbers in parenthesis (#) refer to the notes just below the table. Names in parenthesis are hunches.

| ID (hex) | Period [ms] (1) |

No of data bytes |

byte 0 | byte 1 | byte 2 | byte 3 | byte 4 | byte 5 | byte 6 | byte 7 |

| 300h | 10 | 5 | Current (2) | Voltage (3) | Flags (4) | 00h | ||||

| 310h | 100 | 7 | constant (7) | constant (8) | constant (9) | constant (10) | Temperature (11) | (Charge Limit) (12) | (Discharge Limit) (13) | |

| 320h | 100 | 5 | (DTCs?) (14) | (DTCs?) (14) | Flags (15) | SOC (17) | ||||

Notes:

- h = hex value; d = decimal value; b = binary value;

1) How often this message is repeated

2) Battery current. Raw reading, relative to reading at 0 current (typically 05DCh), positive when current is sourced out of the battery. 16 bits? Units: 25 mA. Range (if 16 bits & 25 mA): 100+ A out to 37.5 A in. Examples (assuming that at 0 current the reading is 05DCh): Observed momentary current draw as high as -135 A out via clamp meter.

|

12 or 16 bits & .25mA

|

12 or 16 bits & .50mA

+37 A of charge seems to low, musing .50mA increments |

3) Battery voltage. Relative to 180 V. Units: V. Range seen: 312 to 366 V. Examples:

- 78h: 300 V

- 96h: 330 V

4) Byte of flags. If the specified item is active, the bit is 1. Else, it is 0. 0 = unused or unknown bit.

| bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| function | 0 | 0 | 0 | Safety plug removed | 0 | Contactors on | Precharge relay on | 0 |

6) Byte of flags. If the specified item is active, the bit is 1. Else, it is 0. 0 = unused or unknown bit.

| bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| function | Safety plug removed | HV connector unplugged | 0 | 0 | 0 | 0 | 0 | 0 |

7) unknown. Always 8Ch

8) unknown. Always 78h

9) unknown. Always 50h

10) unknown. Always 3Ch

11) Pack temperature, relative to - 90C. Units: C. Insufficient data points to confirm this. Examples:

- 104 = 14 C

- 90 = 0 C

- 82 = -8 C

12) Charge Current Limit or something related to temperature? When first turned on, this item starts at a value, then drifts down to another value and stops. Turn off, turn on, and the item restarts at the same value where it started before. The values are very similar to the Temperature values. Needs more study.

13) Probably Discharge Current Limit. Units: A? Range seen: 75 to 155. Related to the State of Charge according to the graph on the right, and these approximate formulas:

- SOC < 18Ah (= 394d): value = 1.57 * SOC - 470

- 18Ah < SOC < 19Dh : value = 18.52 + 0.33 * SOC

- SOC> 19Dh (= 413d): value = 155

14) DTCs?

15) Byte of flags. If the specified item is active, the bit is 1. Else, it is 0. 0 = unused or unknown bit.

| bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| function | Safety plug removed | HV connector unplugged | 0 | 0 | 0 | 0 | 0 | 0 |

17) State of Charge. Unsigned 16 bits. Units: mAh? 0.25%?. Range seen by Hybrids Plus, stopped: 349 to 482. When stopped, and charging, the engine stops when the SOC level reaches 01DEh and starts when the SOC drops to 01BDh = 445d. Ryan and Rich seem to have observed values ranging from a minimum of 01B0h at which point the ICE started while driving, to a maximum of 025Eh during heavy downhill regen at which point compression braking began.

The value is 0000h if the HV safety plug is removed.

OBD-II Diagnostic Trouble Codes (DTCs)

The Battery ECU detects and reports many fault conditions.

- The Battery ECU places a Fault Code (DTC) in its message with an ID of ??

- The Engine ECU receives such DTCs (from the Battery ECU and from other devices as well)

- The Engine ECU lights the Malfunction Indicator Lamp (MIL) (a.k.a. "Check Engine Lamp") on the dashboard. (In some cases it does so immediately, in some cases after it receives the same DTC twice.)

Fault codes begin with one of four letters, depending of the 2 Most Significant bits (MSb) of the hex code:

- Ltr MSBs

- P 00 Powertrain: Most faults start with this letter

- C 01 Chassis: steering, brakes, other chassis systems. Faults in the transmission control ECU or electric power steering system

- B 10 Body: Smart entry and Immobilizer malfunction. The only DTCs are B1294 and B2799

- U 11 Network: Faults in the CAN network as well as any other networks (The Hybrid Control System cannot communicate with other components on the CAN bus0

All OBD-II diagnostic codes have five digits.

The first digit in an OBD-II DTC is always a letter, narrowing the fault to one of four different sections of the on-board diagnostic system: a P for powertrain, B for body, C for chassis, or U for network. At present, no other letters are used.

The second digit will be a number; SAE-defined codes, known as generic codes, are identified by a 0 (as above), 2, or 3. Manufacturer-specific codes, which are not defined by SAE, must use a 1 for the second digit. They can mean anything within the system defined by the first digit of the DTC.

| General Disclaimer: (HV) (DC) injury or death hazard, use at your own risk, may void warranty. |

|---|

|

HV (High Voltage) DC (Direct Current) Warning: Traction Battery Packs, Motors, Chargers, and other HV sources could cause serious injury or death if proper precautions are not taken while working on or around such High Voltage Direct Current sources. Use this information at your own risk: There is no warranty expressed nor implied and we are not liable for any of your past, present, nor future actions. Even should you perform these modifications to the letter you could still damage any number of components in your vehicle causing it to no longer function. Even if it appears to function properly your actions may cause it to self destruct with collateral damage to surrounding properties other than your vehicle. By utilizing these ideas and instructions in an attempting to enhance national security, reduce gas consumption, vehicle "emissions", your carbon footprint, or smog, you do so at your own risk & peril. Warranty: In performing some of these modifications you may void your warranty with the vehicles manufacturer. See also our My wiki:General disclaimer |