|

General Disclaimer: (HV) (DC) injury or death hazard, use at your own risk, may void warranty. |

File list

Jump to navigation

Jump to search

This special page shows all uploaded files.

| Date | Name | Thumbnail | Size | User | Description | Versions |

|---|---|---|---|---|---|---|

| 21:23, 31 December 2006 | Batterypack hvac.jpg (file) |  |

102 KB | DavideAndrea | Ford Escape HVAC components | 1 |

| 20:47, 31 December 2006 | Batterypack airflow.jpg (file) |  |

149 KB | DavideAndrea | Air flow in the Escape's HVAC system | 1 |

| 23:58, 22 December 2006 | AllCanMessages.gif (file) |  |

10 KB | DavideAndrea | All the Escape CAN bus messages | 1 |

| 00:55, 22 December 2006 | Batterypack converter.jpg (file) |  |

37 KB | DavideAndrea | Jump Start Converter from the battery pack | 1 |

| 00:55, 22 December 2006 | Batterypack controller open.jpg (file) |  |

82 KB | DavideAndrea | Controller from the battery pack, open | 1 |

| 00:54, 22 December 2006 | Batterypack controller.jpg (file) |  |

45 KB | DavideAndrea | Controller from the battery pack | 1 |

| 00:45, 22 December 2006 | Batterypack locations.jpg (file) |  |

114 KB | DavideAndrea | Location of components inside battery | 1 |

| 00:07, 22 December 2006 | HV connector battery.gif (file) |  |

2 KB | DavideAndrea | HV connector pin-out, battery end | 1 |

| 00:06, 22 December 2006 | HV connector cable.gif (file) |  |

1 KB | DavideAndrea | HV connector pin-out, cable end | 1 |

| 00:06, 22 December 2006 | Control connector battery.gif (file) |  |

3 KB | DavideAndrea | Control connector pin-out, battery end | 1 |

| 00:05, 22 December 2006 | Control connector cable.gif (file) |  |

3 KB | DavideAndrea | Control connector pin-out, cable end | 1 |

| 00:04, 22 December 2006 | Acdc connector battery.gif (file) |  |

1 KB | DavideAndrea | AC/DC connector pin-out, battery end | 1 |

| 00:03, 22 December 2006 | Acdc connector cable.gif (file) |  |

1 KB | DavideAndrea | AC/DC connector pin-out, cable end | 1 |

| 20:38, 21 December 2006 | Battery block diag.gif (file) |  |

32 KB | DavideAndrea | Block diagram of the Traction Battery in a Ford Escape Hybrid | 1 |

| 18:35, 21 December 2006 | Battery wiring diag.gif (file) |  |

52 KB | DavideAndrea | Wiring diagram of teh Traction Battery in a Ford Escape Hybrid | 1 |

| 23:02, 17 December 2006 | Mostly Finished Batt Box.JPG (file) |  |

661 KB | Cewert | Mostly finished battery box. Holes still need to be drilled into the angle irons to bolt down, and bolts will be added in the middle between the trays to bolt the top of the pack to the bottom. Also, mounting frame is not completely cut to size. | 1 |

| 23:00, 17 December 2006 | Batt Box with Bolt Down Angle.JPG (file) |  |

676 KB | Cewert | Shows the aluminum angle iron that sicks out of each side to bolt the battery box top down to the car. Waiting to drill holes until it is actually mounted. | 2 |

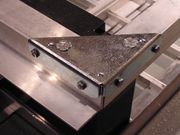

| 22:57, 17 December 2006 | Finished Corner.JPG (file) |  |

685 KB | Cewert | Finished corner with ground of screws. I'm pretty sure this isn't done the official CalCars method. | 1 |

| 22:56, 17 December 2006 | Binding Posts Ground Down.JPG (file) |  |

716 KB | Cewert | These are the binding posts I choose to use. The one on the left is ground down to fit and the burs are also ground off. I'm sure there is a better way to do this, but it worked. | 1 |

| 22:54, 17 December 2006 | Inside Corner.JPG (file) |  |

635 KB | Cewert | Inside the corner bracket. The machine screws are counter sunk into the aluminum angle iron. | 1 |

| 22:51, 17 December 2006 | Plexiglass Shield.JPG (file) |  |

717 KB | Cewert | I choose to install a plexiglass 'shield' on the side of the aluminum angle iron to reduce the risk of a wire / terminal hitting the aluminum and arcing. I am not sure if that is in the official CalCars plans or not. It is held in by non-conductive nylo | 1 |

| 22:43, 17 December 2006 | Batt Box Top 3 Angles.JPG (file) |  |

696 KB | Cewert | Aluminum angle irons cut with 45 degree angles and laid on top of the battery box | 1 |

| 01:30, 16 December 2006 | Batterypack-power-conn.jpg (file) |  |

37 KB | DavideAndrea | Ford Escape, battery pack, power connectors | 1 |

| 01:28, 16 December 2006 | Batterypack-data-conn.jpg (file) |  |

38 KB | DavideAndrea | Ford Escape, data connectors | 1 |

| 01:27, 16 December 2006 | Batterypack-open2.jpg (file) |  |

130 KB | DavideAndrea | Ford Escape, battery open, view from the front | 1 |

| 01:25, 16 December 2006 | Batterypack-open1.jpg (file) |  |

133 KB | DavideAndrea | Ford Escape, battery open, front view | 1 |

| 01:24, 16 December 2006 | Trunk-sans-battery.jpg (file) |  |

42 KB | DavideAndrea | Ford Escape, trunk without the battery | 1 |

| 01:23, 16 December 2006 | Batterypack-out.jpg (file) |  |

45 KB | DavideAndrea | Ford Escape, battery lifted out of thetrunk | 1 |

| 05:34, 15 December 2006 | Top Battery Box With Corner Bracket.JPG (file) |  |

718 KB | Cewert | Corner bracket is just sitting on the top of the battery box waiting to be screwed down. | 1 |

| 05:33, 15 December 2006 | Top Battery Box 45 Degree Cuts.JPG (file) |  |

728 KB | Cewert | The aluminum angle irons are cut with 45 degree angles so they fit snugly | 1 |

| 05:31, 15 December 2006 | Starting on the Top of Battery Box.JPG (file) |  |

723 KB | Cewert | Bottom is mostly assembled, now starting on cutting the angle irons for the top. | 1 |

| 05:29, 15 December 2006 | 2 Trays with Some Supports.JPG (file) |  |

752 KB | Cewert | 2 of the trays sitting on 2 1-1/2 angle irons (others just sitting there) | 1 |

| 05:19, 15 December 2006 | 4 Finished Trays.JPG (file) |  |

746 KB | Cewert | 1 | |

| 05:18, 15 December 2006 | Finished Tray.JPG (file) |  |

712 KB | Cewert | 1 | |

| 05:17, 15 December 2006 | Screws Sticking Through Partially Assembled Tray.JPG (file) |  |

616 KB | Cewert | I used extra long, self threading screws, so they stick through. I used a hacksaw first, and then a dremel with a metal cut off attachment to cut the screws at the base. Then used a grinder to grind them perfectly flat. | 1 |

| 05:14, 15 December 2006 | Closeup of Sample Finished Corner.JPG (file) |  |

705 KB | Cewert | This is just a sample I tried on a scrap pieces before doing the real thing. | 1 |

| 05:12, 15 December 2006 | Holes drilled in aluminum.JPG (file) |  |

665 KB | Cewert | Holes drilled in the aluminum. Used the dremel to drill through both angle irons in the same place, then drilled a larger hole in the top (so the screw would go through without threading and then countersunk it with a much larger drill bit. | 1 |

| 05:10, 15 December 2006 | Tray Parts Laid Out.JPG (file) |  |

721 KB | Cewert | All the parts of one tray laid out | 1 |

| 05:08, 15 December 2006 | Dremel Drill Press.JPG (file) |  |

604 KB | Cewert | This is the Dremel drill press I used to drill the small holes in the angle irons. | 1 |

| 05:06, 15 December 2006 | Almost Finished Tray Jig.JPG (file) |  |

633 KB | Cewert | 1 | |

| 05:04, 15 December 2006 | Making Tray Jig Step 3.JPG (file) |  |

623 KB | Cewert | Place wood to hold the channel irons in place | 1 |

| 05:02, 15 December 2006 | Making Tray Jig Step 1.JPG (file) |  |

665 KB | Cewert | Step one is to place wood around the outsides of the angle iron to hold the angle irons in place. | 1 |

| 05:01, 15 December 2006 | Making Tray Jig Step 2.JPG (file) |  |

656 KB | Cewert | The set together tray with batteries and wood secured in placed around the outsides to form the jig. | 1 |

| 04:58, 15 December 2006 | Tray Ready for Jig.JPG (file) |  |

674 KB | Cewert | This photo is of the tray set together on a sheet of plywood (wich will be used as a jig to hold everything in place for drilling holes. | 1 |

| 04:56, 15 December 2006 | Tray Set Together Close Up.JPG (file) |  |

693 KB | Cewert | 1 | |

| 04:55, 15 December 2006 | Tray Set Together With Battery.JPG (file) |  |

725 KB | Cewert | 1 | |

| 04:54, 15 December 2006 | Tray Pieces.JPG (file) |  |

704 KB | Cewert | These are all the aluminum pieces needed to build the 4 battery trays. | 1 |

| 04:51, 15 December 2006 | Cutting Aluminum.JPG (file) |  |

704 KB | Cewert | 1 | |

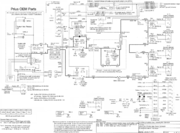

| 08:53, 13 December 2006 | EAA-PHEV-PRIUS-HighPowerSchematic.png (file) |  |

356 KB | Rjf | These are the high power schematics from the latest PriusPlus conversion. V3r2_061210 | 1 |

| 17:22, 6 December 2006 | Day 4 Image 9.JPG (file) |  |

65 KB | Rjf | brightness adjusted. | 2 |